As a steady growth becomes a norm for Marine and Boating industry for several years, rigorous developments have shown an upward slope in recent times. 2016 is anticipating a strong year for the marine industry, especially for the developments in electronic instrumentation. With plenty of new innovations and product launches happening in boating and marine markets, high protection and safety becomes a serious concern against unpredictable environment. The highest uncertainties addressed in Marine industry is the risky climatic reactions due to global warming. So the main game to survive in the market is the protection of electrical assets from destruction. With this, the cable glands are highly in use to provide a protective coat to the cables that can maintain the electronic systems, increase the lifespan of the instruments and save the destruction cost in the Marine industry. The innovations have offered a wide range of customized cable connectors to perfectly suffice the safety needs of Marine businesses. This article drives you to the functionality, materials used, applications, types of cable glands and the recent innovations in the marine technology.

For a proven design, engineering and manufacturing the marine instruments and machinery, cable glands are at the nucleus for the safety of marine assets and other tough applications. Submarines, cranes, underwater instruments, marine gauges, weather sensors, antennae, temperature alarms, galvanic Isolators, flood detectors and many more have installed cable connectors to provide a protective coat to the cables connected to these instruments. For these, the cable gland manufacturers provide a hermetically sealed solution for the marine cables and marine pipe transmission.

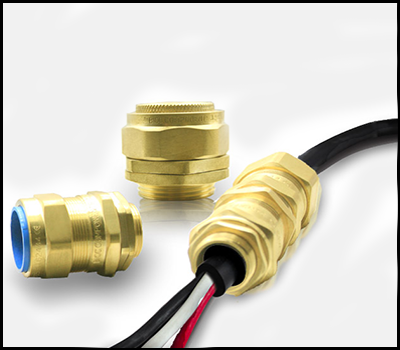

This year (2016) has marked a serious competition among the cable gland fabricators to deliver high quality cable gland and cable fittings with customization being an added value to the cable gland products. In addition to this, the size, shape, dimensions and material melds are vital aspects of consideration to provide customized cable glands. Also for luxury yachts, ships and submarines, polished cable fittings are main requirements. For marine cable glands, high grade materials like plastic, aluminium, stainless steel and UV stable nylon are used to offer a qualitative product to the customers as per their needs.

For the marine vessels which needs compact cable fittings, UV stable nylon material is used for cable gland with single/twin cable entry. These types of cable gland are waterproof in nature and are highly in use for solar panel installation, navigation lights and other marine devices and instruments. The plastic cable glands are easy to fit and while installation even the existing glands need not be removed. For these types of cable glands, the manufacturing process includes a stringent waterproof and dust test. The anodized aluminum that is of marine grade material is used in the construction of aluminium cable glands with its application in marine equipments. The stainless steel cable glands have a captivating low profile shape that is used in luxury vessels and waterproof cable transits. For BNC coax connection in VHF radios, cable glands with splitting seals are used.

The robust development in marine market has high application of cable glands in new marine technologies. Recent innovations are seen in Propulsion Technology used in electrical and gas turbines. This technology is extensively used in naval marine vessels. The propulsion system made it possible to achieve an optimum level of fuel usage and operating costs. The cable glands are used in motor, control system and generator installed in the marine engines and gas turbines. The low pressure gas admission system used in two stroke engines with dual fuel concepts uses durable cable glands for its marine usage. Marine scrubber system and emission controlling/ monitoring system uses tough cable fittings in emission control technology with turning the ratio of environmental protection standards parallel to the profit margins. The vessel efficiency technology uses quality cable coatings to minimize the risk of damages. The hybrid crane technology for above and below deck machinery has high application of tough cable connectors and fittings. It also has its application in the efficient steering systems in huge marine vessels. The Ballast Water Management System also requires electrical safety coating for the cables installed in the system of marine vessel. The UV stable cable glands with dust and waterproof features are used for safe electrical connections in the combined gas turbine with the electric and steam system which can operate on various fuels to protect the environment.

With the worldwide greenhouse gas emission, the marine industry has sensed a strong need for innovations in environment protection systems in todays era. Thus, with the increase in requirement of safety system in the electronic instrumentation, cable glands are at the rim of the basket for the marine market across the globe with its application triggered for environmental, human science as well as for the economic benefits of business.

To get a consultation on cable glands, visit https://www.bicccomponents.uk.com/industrial-cable-glands/

SUBSCRIBE TO OUR BLOG

SUBSCRIBE TO OUR BLOG