With the trend of innovations, project expansion and new discoveries flowering into varied industries, a secured cable system is becoming a prime facet to increase the quality and estimate life of the electrical equipment and electronic control systems. Todays era of high business risk in implementing and above all maintaining the new electrical installations, accounts for an intact and protective cable management system. Going into the technicalities of how cable glands and cable cleats are a crucial part of electronic safety and security project, this article will catch a glimpse about what are cable cleats? Where are they required? And how can it reduce the mechanical load of cables that are affected by short circuits?

A high demand for quality cable cleats is marked in automation, Oil and Gas, marine, water treatment and water works, mines and quarries and many other heavy duty projects where safety of assets is at the rim of the basket to refrain from the loss due to deterioration or destruction of equipment and electronic assets due to climatic reactions and hazardous situations. To know more about the Cable Cleats, let’s have a short drive into the roots of cable cleats to understand its importance in reducing the mechanical load of cables that can avoid the explosion.

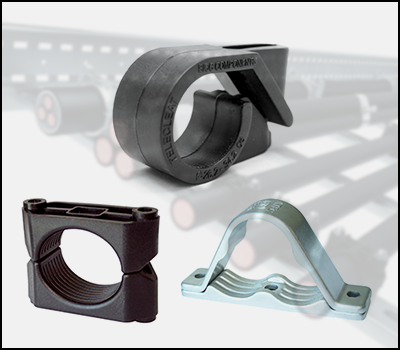

A cable Cleat is a cable restraint device anchored to a mounted surface that is designed to provide retention and security of single conductor or multi conductor cables that are subject to the lateral, axial or torsional forces. Apart from its rich feature of strain relief, cable cleats helps reduce the mechanical damage of high, medium and low voltage cables that is caused due to short circuits. It consists of a rough and tough interlock frame that encloses the support rung and cables.

These have their application in the installation of the high, medium and low voltage AC and DC system, single cable configuration with single conductor, trefoil configuration with single conductor cables, multi conductor cables, cables used in hazardous and extreme environment, cables that have a direct contact with the aggressive external forces ( vibrations, short circuits & cyclical loading, seismic movement), vertical cables with long straight cable runs with strain relief feature and many more applications where cables need high security from the hazardous environment. Apart from these, it can also be applied in an under strained cable system with retrofit installation or any type of cable installation where certification of cable system should be in compliance with national wiring standards.

What befalls to the cable during short circuit and how cable cleats help reduce the mechanical load of cables?

As the altering current directs the repetitive oscillating alignment, it results in the repulsive forces between the conductors during short circuits. This repulsive electromechanical force regulates constant fluctuations in the direction and its magnitude. It is important to mark that these electromechanical forces are the root cause to damage the cables. Digging more into the details, as the high current flows through the resistance of conductor directly hits the cable, it results into a lateral and axial thermal expansion. And as a result of the blending of electromechanical forces with the thermal expansion, cable bowing and cable bending (cable deflection) takes place that creates an axial pull on the cable termination. This causes the uncontrollable whip of cables till the current is exhausted, resulting in unleashing of safety concerns with mechanical damage to the cables.

Here comes the main role of Cable Cleats in reducing the mechanical load of the cable. The cables restrained by the cable cleats are highly used for the secured application where they are directly exposed to high current and short circuits. Be it high, medium or low voltage cables, the cable cleats helps protect from the mechanical damage due to short circuits. cable cleats retain and supports the conductors and cables with reducing the mechanical load of cables that is exposed under its own weight. This in turn helps protect all the cable termination installed in the cable system. Without the cable cleats, it can also result in harm to people in addition to high financial cost for replacing a damaged cable management system.

BICC Components Limited (BICC) is an expert distributor and manufacturer of cable gland, cable cleats, copper terminals, cable fittings and other cable accessories that are rough and tough to protect from the mechanical damage of the cables during short circuits. It proffers rigorously tested and highly durable cable security solution to varied industries. To know more, visit https://www.bicccomponents.uk.com/. Feel free to get a consultation or to get a quote, visit https://www.bicccomponents.uk.com/contact/

SUBSCRIBE TO OUR BLOG

SUBSCRIBE TO OUR BLOG