As the technology glamorizes to make a killing, instruments are turning more compact, customized, multi-featured, lightweight and handy with breaking the boundaries of innovation in current times. With this, many planners skip on the cable security concern while designing a machine, robot, high-tech tools or an electronic device. This can end up putting an electrical instrument into a big failure or a flop show if cables are not properly placed and tied at particular interval to control the movements in case of short circuit, extreme temperatures, explosion and other fault conditions.

So, a simple solution for a clan of technology experts addressing all together varied new electronic outfits that need improved cabling system should know the significance cable cleats. Be it installing a cable cleat in underground location, outdoor environment or indoor application, it always proves to be cost effective and reliable to probe into the harmful effects of the harsh movement of cables in abnormal conditions. Let’s take a further read into the cause and effect of movement of cables and more details on the Cable Cleats that minimize the movements of the cables during faulty or normal conditions that supports to scale back the cost of rework and increasing the estimated life of the machine?

With the chic automation in vogue, all the upcoming process, machinery and techniques are designed to function at a faster pace than the previous version with installing multi features and sensor systems to make it a unique up gradation. These kinds of automation can tense and pressurize the cables beyond its performance capabilities. Also the subsea cable installation calls for high grades of protection that is possible with the help of an up graded underwater cable gland system. At the very beginning of this year 2017, there exist 428 subsea cable systems approximately in service across the globe. Herein, the movement of cables needs a sheer control due to the current abrasion, subsea seismic activities or underwater landslides apart from the other natural oceanic hazards. All these types of external environment need a proper hold on cables to minimize their movement and avoid further damages to the cabling system.

Folks! It is pretty clear on the parallel relation between cable stresses with that of reliability of electronic equipment. Understanding the domino effect of the movement of cables will allow the technology freaks to take simple precautions on it with installing appropriate cable cleats that can save the rework cost and protect the equipment from heavy damages in a difficult climate.

Causes and effect of movement of cables:

The mechanism and operational conditions in current times are becoming much faster such that there are chances of cables flex ending up into rolling, torsional, tick-tock and random flexing motion. The shields and copper conductor is stressed each and every time a cable flexes or bends. Also copper has lack of or very low resistance to stress that can result into a wire breakage.

Let’s take a short drive into the causes of cable movements! There are few common causes of cable failure due to its flexing in normal or rigorous motions. Many a times, constant erosion and abrasion of the cable caused by other hoses, cable and cable management hardware can end up causing degradation of cable jacketing and conductor insulation. This is due to coming in contact with the plastic or metal chips, lubricants or solvents that attack conductor insulation and cable jacket. Also the cable jackets start reacting to extreme temperature and vacuum.

These issues can result into short circuit or an explosion damaging the asset and cables at large that asks for a heavy duty rework or for a complete replacement.

The cable movements and flexing can also cause a fracture to the shield and conductor in the flex area. Faster are the equipment cycles, raises the temperature level, causing the insulation to soften that can end up changing its properties for the worst. It lowers the abrasion resistance, reduce the tensile strength and lower the cut-through resistance properties. Also the stress, vibrations and bending of the moving cables can break the soldered and crimped cable to break.

The main defeater that solves these issues:

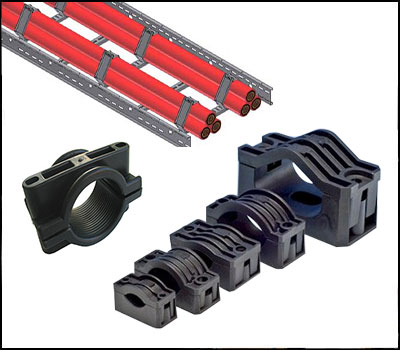

Above all these issues, one of the best ways to reduce the moving of cables is to install an optimum cable gland system with exact cable cleats at regular interval to increase the reliability of cable in the hash, tough and flex conditions.

On the other hand, deriving the best suited cable cleats with a perfect cable design for the required purpose of your project at the initial planning stage itself without making the cable cleat a factor of cost cutting is at the prima facie to avoid increasing cable movements and system failure at large. With cleating the cables, it allows increased acceleration with low oscillation and reduced vibrations to control on the movements of cables.

Along with the cable cleats, to minimize the exhaustion on shields and copper conductors with saving wire from a breakage, the bending radius of the cable should be wide and large as possible. On the other hand, the diameter of the cable should be designed as small as possible to avoid the cable crunch. A proper testing of cable gland and cable cleat is also a sincere concern before installing it in a cabling system to make it a reliable, tough and sturdy one.

BICC Components Limited (BICC) offers a reliable solution to control the movements of the cable and to get an accurate cable gland system installed with cost effective techniques of cable cleating. Our clients from varied industries have made it possible for our team of experts to proffer a complete turnkey cable protection solution by offering a wide range of cable glands, cable cleats, cable fittings and related accessories that save the cables from a breakdown. To probe into our range of cable cleats, visit https://www.bicccomponents.uk.com/cable-cleats/. Also plug into https://www.bicccomponents.uk.com/contact/ to connect with a technical expert or to solve your queries or to get a quote.

SUBSCRIBE TO OUR BLOG

SUBSCRIBE TO OUR BLOG