The importance of cable cleats is often underestimated. Instead of being treated as an integral element of any cable installation, they are often considered as just another electrical part and often face the first axe of cost cutting. The fact however remains that to ensure that a cable installation is safe cables need to be restrained so that they can withstand the forces generated. Without the usage off cable cleats there cannot just be costly damage to cables but also a substantial risk to life.

This is more so, since forces between cables are known to reach their peak in the first quarter cycle. While circuit breakers interrupt the fault after three to five cycles by which time the cables are destroyed, cable cleats serve as the perfect antidote to this problem.

It does not however work to install just about any cable cleat since it is imperative that there be the best fit for a cable cleat so that they ensure the support of cables and reduce the load they are subjected to. Properly fixed and supported cables will ensure that in the event of a short circuit fault condition, the cables will be protected ensuring that the circuit can be restored once the fault has been rectified.

ABLE CLEAT AND ACCESSORIES SPECIALIST

Cable Cleat Selection

Selection of the right cable cleat takes into account a whole lot of factors including the cable type, design and environment. Here is a quick overview on the factors to be considered before choosing the right cable cleat.

Cable Type

The factors to be considered here include:

Diameter – The diameter of the cable will in turn dictate the size of the cable cleat as also calculate the short circuit forces that the cable cleat may be subjected to.

Performance – Since cables are available to thrive in different environments and can have fire performance, low smoke or zero halogen requirements, the cable cleat will also need to adhere to these requirements.

Cable Format – In choosing the cable cleat, due importance should also be given to whether the cable is single core or multi core and whether the voltage is low, medium or high.

Design – There are several factors that you would need to consider while looking at the design. These include:

Mechanical Load – Cable Cleats need to be checked for axial and lateral loads so that they are fully ready to support the weight of the cables.

Short Circuit Rating – A key determinant of choosing the right cable cleat is to figure out the maximum peak fault that the cable may be subject to under short circuit conditions. Calculating the short circuit rating will help determine the maximum force that the cable cleat will be able to withstand during a short circuit.

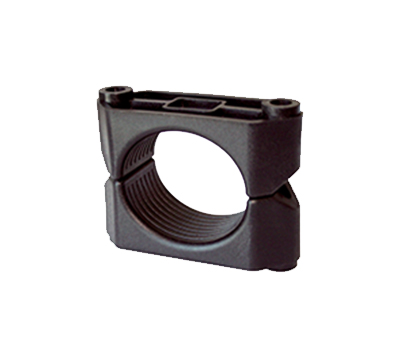

Cable configuration – The type of cable cleat is also determined by the cable configuration. You may need to look for a single cable cleat, a trefoil cable cleat or a quad cable cleat. There can also be bespoke cable cleats which are designed taking into account the exact requirements.

Cable run length – Depending on the overall cable run length, the number of cable cleats required can be determined. For cables that run through a ninety-degree angle, it is to be noted that the spacing will be reduced through the bends.

Expansion – In choosing the cable cleats it is also to be considered whether the cables are single core or multicore. Single core cables are known to expand and contract more on account of temperature changes vis-a-vis multicore cables. If the cable is constrained the force is typically transferred to the supporting structures. To avoid this, therefore, single core cables are snaked as also the cable cleats are allowed to move freely.

Other than understanding the various factors that determine the choice of the best cable cleat, it is also important to choose the right partner who can advise you on the right cable cleats given the above factors. Every so often the choice of a cable cleat is left to a third-party certification. However, there are many nuances to consider. For example, if a cable cleat has a quoted short circuit withstand, it is typically assumed that this is all that one needs to know. The fact however is that one needs to get into a level of detailing to understand that the level of withstand is typically valid for a cable diameter equal or greater than the diameter of the cable. In case you land up using smaller cables, the level of withstand will not hold. These specifications are best known and taken care of by an experienced provider. With over three decades of manufacturing experience, Cable Cleats are therefore recommended for different installations to suit a variety of bespoke applications.

SUBSCRIBE TO OUR BLOG

SUBSCRIBE TO OUR BLOG