When it comes to installing cable cleats, the general tendency is to treat them like any other accessory. Little surprise then, that it is generally the cost that leads to their choice. The fact, however, remains that cable cleats are akin to insuring yourself. When you buy insurance, the hope is that it should never be used. Yet, if the unfortunate situation where it needs to be used, does present itself, the insurance should be robust enough to help you through troubled times. So it is with cable cleats!

The fact is that in the focus on costs and bottom line, if the choice of cable cleats is compromised, it can turn out to be an extremely costly mistake, should there be a short circuit. The lack of proper cable cleats can prove to have a disastrous impact that can push a project behind by several years. Not only can it lead to costly rework, which could mean replacement of cables, operational downtime and more, there is also the fear of loss of reputation for the company as also loss of precious lives.

Cable cleats, in fact, are designed for harsh environmental conditions where short circuits are common. With the change in temperatures, warping is the norm and if there isn’t a reliable cable cleat, a short circuit ensues, causing damage to materials and life. On the other hand if there are reliable cable cleats that have been installed, they ensure that the cables are supported and that the load exerted on them is minimized while also preventing damage during fault conditions. If, purely on account of cost, a circuit breaker is used as opposed to a cable cleat, the damage to the cables may have already occurred. This is because a typical circuit breaker interrupts the fault after three cycles while damage to cables under fault conditions generally occurs within the first quarter cycle of the fault.

To prevent this, it is imperative that cable cleats with the right specifications be used to withstand different short circuit levels. Not only do you need to keep in mind the short circuit withstand level of different cable cleats, what is also important is to keep in mind the cable diameters.

Choosing the cable cleats, the following issues need to be figured:

- Cable diameter

- Performance

- Cable Format

- Design

The fact remains that while engineers fully understand these aspects and their importance, cable cleats get shot down on account of the fact that they tend to increase the overall project cost. What is ignored, however, is the fact that the costs incurred in case of an exigency in terms of cost of material, manpower, operational downtime, and more, far exceeds this cost, several times over. What is needed, therefore, is to treat cable cleats as a vital aspect of the installation, as opposed to looking at it as any sundry item.

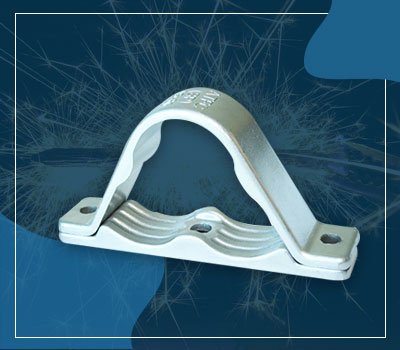

As a widely trusted cable cleats manufacturer, BICC offers a wide range of options to meet the bespoke requirements of different projects. cable cleats are available in metallic as well as non-metallic types. Epoxy cable cleats are found to be particularly effective in highly polluted areas. Our brass Cable Cleats as well as Aluminium cable cleats are known to work well for a range of applications. In addition, there are also the stainless cable cleats that are specifically designed for low, medium and high voltage cables, while the two-bolt cable cleats work well with horizontal and vertically routed HV cables. BICC has also introduced the popular Trefoil Aluminum Cleat to suit a variety of applications, including heavy-duty variants.

At BICC Components Limited (BICC), we are totally committed not just to provide a wide range of cable accessories but complete peace of mind for your project. Irrespective of whether you have an oil and gas, mining or shipbuilding project in the harshest of conditions, we have you fully covered against short circuits. With our reliable cable cleats, you can rest assured that what you have in place, is a handy tool to minimize any disruption and damage to your project and ensure everything works smoothly.

With our commitment to quality and support, you can rest assured that the safety and protection to your infrastructure project, is a given, we take great pride in being able to offer bespoke cable cleats solutions for a range of highly complex applications. Request for a quick quote to get a wide range of cable cleats!

SUBSCRIBE TO OUR BLOG

SUBSCRIBE TO OUR BLOG