Electrical cables are an important or rather a mission critical part of most transportation systems. Automobiles, mass transit even military transport use electrical and hydraulic system. Whether you commute by car, bus or take the train, you would have encountered electrical and hydraulic systems yourself. This could be by way of rolling down those power windows in the car or going through powered doors. It is the jacketed cables that carry electric current to the necessary area. Similarly hydraulic systems carry fluids to brakes. While the cables are critical element in the automobile’s success, what is critical is securing the cables and hydraulic hoses both for the performance of the vehicle as well as for providing passenger safety are cable cleats. Essentially cable cleats are cable resistant devices that provide security and retention of cables thereby ensuring passenger safety. They are especially important where cables are exposed to axial, lateral or torsional forces that are caused by the weight of the cable or short circuit fault currents.

Considering that they are installed on the vehicle’s undercarriage, it is extremely important that they be properly designed and made from the right substances so that the can withstand the tough conditions that they are subject to. In buses, for example, a cable cleat is subject to extremes of sunlight and more, while in a snowplow they are subject to extremely low temperature and chemicals.

Non-metallic cable cleats are typically known to suit most installation environments while epoxy coated cleats work best for industrial and polluted environments. Aluminum cable cleats are also widely popular especially in heavy duty variants. In case the range of temperature is huge, rubber cable cleats are often preferred.

The cable cleats can be molded to adapt to different shapes and sizes basis the conduits they need to support. They ensure that the cable is adequately supported so that it does not crumble under its own weight. The cable cleats ensure that the mechanical load exerted on them is reduced. Even in case of a short circuit, the cables are not damaged and once the fault is corrected, the circuit is restored. Cable cleats, therefore, ensure that:

- Cables and conductors are adequately supported

- Reduce the mechanical load of the cable

- Reduce the mechanical load of the cable termination

However, it is imperative that to ensure passenger safety the cable cleats are chosen with care as per the following parameters:

- What is the type of cable being used- It is important to consider if the cable is single or multi-core and whether it is low, medium or high voltage.

- What is the maximum peak fault that the cable can be subject to

- What is the cable configuration- The cable configuration will determine whether the cleat required is single, trefoil, quad or whether a bespoke cable cleat is required

- Cable run length- The cable run length will determine the number of cable cleats required.

- Single core or multi core cables- Single core cables are known to expand and contract more, hence it is advisable to allow the cleats to move around.

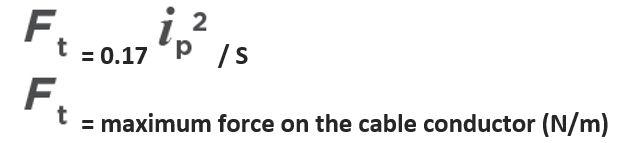

When it comes to cleat spacing, the tensile strength required by each cable cleat is as below, depending upon fixing centers.

Paying attention to the above parameters will ensure the use of the right cable cleat which will in turn ensure safety.

While some amount of protection can also be obtained by using a circuit breaker instead of a cable cleat, however if the fault occurs within the first quarter cycle, the circuit breaker cannot open and it can damage the cable management system. Typically a circuit breaker interrupts the fault after three cycles, by which time the cable has already been damaged. Not only is this costly, the added expense is also on account of the operational downtime.

With the many tests to ensure that cable cleats are resistant to electromechanical forces can withstand short circuit, go a long way in ensuring that passenger safety isn’t compromised.

It is therefore prudent that the importance of cable cleats is not undermined and that they are treated as a valuable component instead of being considered just about any electrical sundry and be subject to cost cutting. Looking at things from a budgeting point of view alone may amount to reducing the cost of the cleats, however it does not take into account the time, energy and the cost that may accrue should the entire cable management system have to be replaced. The importance of the additional expense towards the cost of cleats is therefore easily justifiable.

Importantly, without the use of cleats the dangers amount to not just costly damage to cables but also a threat to precious life.

SUBSCRIBE TO OUR BLOG

SUBSCRIBE TO OUR BLOG