The importance of the cable gland installation stems from the fact that having a high degree of panel integration during and after installation can give fortunes of smooth functioning and high security of the cabling system. The cable glands are installed in every kind of panel construction and electrical equipment to fortify and maintain the panel integrity at the entry point of cables. The typical and common process to ensure panel integrity involves drilling holes into the panel to allow the cables to pass smoothly through various electrical system. In order to seal all the gland openings between the fitting, enclosure and cable, the secured strain relief is provided by finely crafted tech savvy design to mount the enclosures. This is the basic method to ensure panel integrity in cable glands. This article puts forward the vital and smallest of operations that help achieve a suitable point of panel integrity in the installation of the cable glands.

The panel integrity is one of the toughest and significant stint in the cable gland installation that is defined by IEC and NEMA standards such as IP65, IP67, I68 and so on. The cable glands get different ingress protection ratings depending on the use of washers and seals between the gland & cable or the gland & equipment that helps decide the level of cable glands that can bare wash down. Let’s get exposure to how cable glands have smooth panel integrity with a strong ground work to minute operations for constantly maintaining technical integrity during and after cable gland installation.

The casting of the cable gland is done with a high degree of testing and inspection of the smallest detailed process involved to increase sealing ring performance with high durability and reliability. These include right choice of material melds, strong testing mechanism and proven cable sealing design. The exact cable gland size, the number of Spanner Turns required, the actual diameter of cable, etc. are the vital details that are considered before commencing for next stage of installation. Going more into the technicalities that will make it easy to gulp the reason behind smooth panel integrity in cable connectors!

Right Medley Of Material Melds

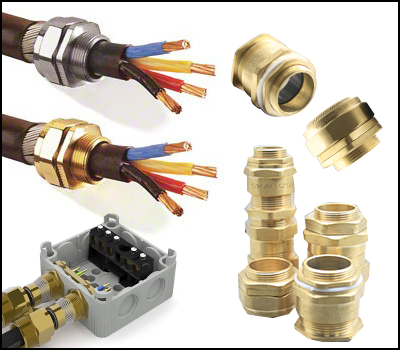

cable connectors, cable cleats and copper terminals offer varied viable options based on the purpose and environment where it will be installed. Many kinds of combination of material inputs are used that include stainless steel, plastic, aluminium and brass cable gland. On the other side, whether shielding, impact resistance, cost and panel material to which the enclosure is mounted are a sincere point of concern being a prime part of planning stage to select on the right type of cable gland to be installed for a particular cable protection project.

Armor Clamping

The clamping ring and armour cone is crafted to be strongly tightened with metal to metal having termination process to be correctly implemented at the first time that finely blends the armour wire in crimping operation. The armor termination is engineered and designed to terminate a variety of armour sizes be it – pliable wire armor, single wire armor, strip & tape armor or wire braid.

Mounting

The cable gland is threaded into tapped or drilled holes or they can be fed into a clearance hole. To get an extra level of security, a lock nut is installed in the threaded portion. A fine variety of an extended threaded models of mounting cable glands suit best for the enclosures that have unique requirements.

Stability In Earth Continuity

The Armour Clamping techniques ensure low impedance termination is maintained that gives a room for a strong reliability in earth path. This in turn creates a wall for potential equalization to get adversely affected cable glands that encounter low performance and durability.

Cable Diameter

Being a strong element of the initial steps in selection of cable gland type, cable diameter that is viable to provide a sealed interface inside out of the equipment and a constant strain relief should well suit the installation process, be it a multiple entry seal or reduced cable entry variant.

Testing Mechanism

The inspection division of cable gland consists of the strict testing methods with ingress protection, thermal endurance, cable anchorage, pull out and twist resistance test and many more testing operations to get a high panel integrity in the cable gland installation.

Thus the selection process and other small mechanism involved in manufacturing and installation of cable glands becomes a name of the game for a high level of panel integrity during installation. The researchers are now heading towards great transformation in the online selection tools that can help the end users to get assistance in making the right decision to accustom with the required level of ingress protection for cable gland installation.

The BICC Components Limited (BICC) is a trailblazer in the manufacturing and distribution of the cable glands, cable fittings, cable cleats, cable connectors, copper terminals and other cable accessories. Having a well defined tooling room, exclusive testing methods, upgraded technology and a strong team of engineers has made it possible to derive a wide range of cable gland and cable fittings that have a high degree of panel integrity during installation. To get to know about our wide range of products, visit https://www.bicccomponents.uk.com/products/ . Why not give us a call or drop an email in case of any queries or to get consultation? Visit https://www.bicccomponents.uk.com/contact/ to get contact details.

SUBSCRIBE TO OUR BLOG

SUBSCRIBE TO OUR BLOG