When the new innovations started bringing high tech oceanographic equipment and underwater vehicles and machinery into implementation, the limitations of simple cable gland became palpable. With the advent of a wide range of sub aquatic cable glands that are capable of withstanding the extreme depths, the watertight cable connectors are extensively being used in the underwater cabling projects, be it protecting cables from high pressure, extreme temperature, hazardous climate, moisture or dust. Also, rigorous inspection methods for cable glands that include being tested at high pressure over greatest depths are now a part of cable connector manufacturing to cater to the heavy duty electric underwater assignments. This article will furnish you with the properties of underwater cable connectors and how to choose the best suitable cable gland for your subaqueous project. It drags you to upgrade with the basics of underwater cable glands when you are at the crucial state to decide on the watertight cable glands, liquid tight cable connectors, sub sea cable protection, marine cable glands or other cable protection project that needs protection and easy maintaining of the electronic systems to be installed in various underwater climates.

When it comes to investment for securing of cables, many questions roll over mind to ensure the durability of the electronic equipment and devices underwater. Whether the cable gland installed is proper for our project? Is it best to protect underwater cables from moisture and dust? Does it work out to be rough and tough in hazardous conditions? Does it prove to be strong in extreme underwater climates? And many more questions arise while choosing the right cable connector for your project, be it to be installed in the shallow or deep waters.

Let’s have a quick and simple brief about cables connectors!

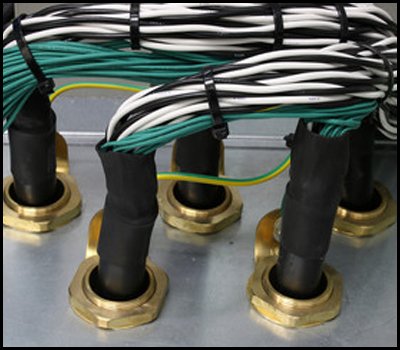

Cable gland is a device in which a cable is passed into an enclosure that helps in stain relief and in protecting the cable from dust, moisture and liquids.

Choosing proper cable gland for the underwater applications:

When it comes to protection of cables underwater, the waterproof cable glands and cable fittings are described as water tight, water resistant or water repellent. Well! To help you ensure and decide on the exact type of cable connector to be used for your sub sea or underwater project is to find the IP rating of the gland you are planning to use in the cable. The most common method to evaluate the level of water resistance the cable gland has is Ingress Protection Rating (IP Rating). This type of rating appears with a two digit number where the first one represents the security rating of cables from the foreign objects such as dust. The second digit represents the level of tough protection from the ingress of liquids. The most demanded IP ratings for water proof cable glands used in manufacturing industry are IP65 to IP68 that provide security from dust and safety of water jackets from all directions.

Let’s get more into the properties and kind of cable gland for underwater applications!

The underwater electric instrumentation needs cable protection from water immersion. The cable connectors have wide applications in the instruments, industrial machinery, process control, marine and many more that also include underwater lights, outdoor security cameras, pond pumps water treatment works, fountains and waterproof LED lights.

These types of cable gland have robust construction that has good resistance to extreme temperature and have dual terminals that can prove beneficial for easy installation and looping of conductors. With varieties in underwater cable glands, there is also high competition seen in the level of customization in each and every type. Apart from the type of material and technique of production, customization is provided in insulation piercing options, configurations, keyway coded, conductor capability, clamp fitting, cable sealing washer and cable sealing ring in current times.

The feature rich cable connectors that are easy to handle, quick to install, abrasion resistance at low or high temperatures have a specific design to get easy and continuous flexibility and bending properties for both, indoor and outdoor application. These kind of cable connectors and copper terminals are ideal and high in use for submersible assignment, marine application, pumps and fountains.

When the underwater or sub sea project accounts for more stain relief properties to protect the cables, a spiral-flex extended version is high in demand that helps prevent kinks and sharp bends in cables. These are tested and proved to be strong at the time of moving marine machine parts or underwater machinery from one place to another.

The standard nylon cable glands with PG or NPT thread or nickel plated brass connectors with either NPT, PG or metric threads are suited for underwater industrial use and corrosive environment. The EMC connectors that are best to shield from the electromagnetic frequencies and highly flexible in blending with different cable shield is also trending in the underwater electronics.

The BICC Components Limited (BICC) has an extensive experience and expertise in manufacturing and distributing of underwater cable glands, fittings, cable cleats and copper terminals. Our offerings adhere to the high quality, simple and complex cable protection application for Submarine, deep sea cable system, liquid tight cable glands, underwater cable protection, marine vehicles and water tight applications. To know more about our wide range of cable glands, visit https://www.bicccomponents.uk.com.To get a consultation or to drop your queries, visit https://www.bicccomponents.uk.com/contact/.

SUBSCRIBE TO OUR BLOG

SUBSCRIBE TO OUR BLOG